Your Position: ARROW Products >> R-CORE TRANSFORMER >> SMALL POWER CONSUMPTION IN R-CORE TRANSFORMER

SMALL POWER CONSUMPTION IN R-CORE TRANSFORMER

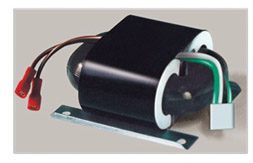

Electrical engineering textbooks lay down the basic requirements of an ideal transformer. Based upon research into these requirements, a highly efficient R-Core Transformer was finally introduced. It can be applied to all kinds of electrical appliances as a power transformer or as an insulation transformer. The most important item in producing a high quality R-Core Transformer is the core.

Our company produces R-Core Transformers itself. We make use of computerized curve slitting machines with stress eliminators to tailor-make R-Core Transformers to satisfy each of our customers' distinctive demands. Our production technology is advanced and the quality of our products has reached the world-class level.

Electrical Characteristics

The R-Core uses Hi-B grain-oriented electrical steel. The precise quantity of materials required to produce an R-Core must be initially calculated. Then the materials go through the accurate slitting and continuous winding processes. Since there is no gap in the body, minute losses in the core and low resistance in magnetic circuit, the flux leakage is very little. As the windings of the R-Core are in the shape of a cylinder, the length of copper wire in each spool can be minimized, reducing the resistance of the copper. Thus, the R-Core Transformer achieves its advantages of lower voltage regulation, high efficiency, low noise, and low flux leakage.

Since the R-Core features a body that has no gaps, and a very tight distance tolerance between the bobbins, the magnetic flux flows extremely smoothly, resulting in very low noise. Additionally, the bobbins are reeled into a cylindrical shape so that tension is relieved to a great extent, making the reeling processes much easier, and the traverse of coil winding more concentrated. Consequently, it reduces the noise that is caused by vibration in the coil winding due to the effects of the strong magnetic force that arises when the conductor is electrified.

The winding portion of each R-Core Transformer is composed of two completely symmetrical segments. Each segment is wound in the opposite direction. Because the leakage of magnetic flux from one segment counteracts that of the other, the flux leakage from each R-Core Transformer is minimized.

Construction and safety

The R-Core Transformer holds the advantages of high efficiency, small size, thin body, light weight, and standardization of production. Because the structure of the transformer is logical, the distribution of capacitance is reduced.

From the design of the R-Core Transformer to the selection of materials, our company currently follows the UL standards as our fundamental basis of production. The entire production process, no matter whether materials, manufacturing, or survey and inspection, is under strict control. Our products are certified to meet the international safety standards of different countries, such as UL, TUV, VDE and CE, etc.

Applications

The no-load power consumption of the R-Core Transformer is sufficiently low to satisfy the increasingly strict demands of various countries regarding the power consumption of electrical appliances. It is especially suitable for those power transformers that are almost completely under the condition of no-load power consumption or long-term stand-by power.

The R-Core Transformer delivers extremely low noise. Its insulating effect is excellent and its output power is large. The R-Core Transformers produced by our precise winding machine function outstandingly when applied in both electrical and audio equipment. They can improve the signal-to-no-noise ratio of this equipment as well as isolate it from interference by the resonant waves of the electric network. As a result, it helps decrease distortion in audio equipment, strengthens its dynamic range, and enhances fidelity.

The R-Core Transformer possesses all of the above-mentioned excellent features. It may be broadly applied in industrial control equipment, home appliances, high-class audio products, signal systems, office equipment, communication facilities, testing instruments, and medical instruments, etc.

|